Radiography

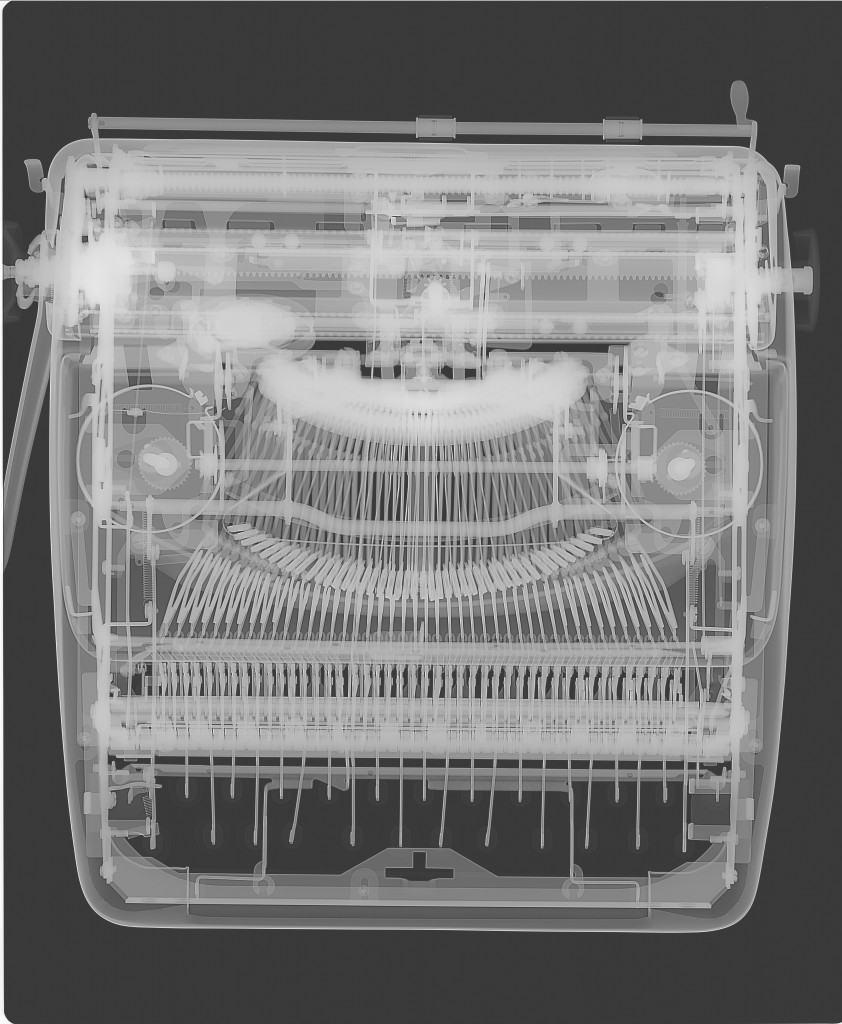

Industrial radiography (RT) is the same as radiology in the medical field. Up to 4″ of steel, 3″ of brass, or 12″ of concrete can be examined. Flaws as small as 1% of the thickness being X-rayed can routinely be detected. X-ray and gamma ray images can be recorded onto film, or digital media including DVD, flash drive or external hard drive.

Radiography

Radiography is carried out using X-rays or Gamma rays. Radiographic testing (RT) is one of the most reliable and widely used NDT methods. RT works on the principles of differential absorption of radiation, and is used to detect internal flaws in castings, forgings, welds and composite materials.

Gamma Radiography

Is a technique which uses gamma-rays to produce the image of an object onto film. The source of radiation is either a gamma-ray tube, which is normally described by the electrical voltage with the higher the voltage the higher the penetrating power of the radiation or a pellet of radioactive material emitting gamma-rays. Applications include wall loss detection and sizing in pipes and plate through to manufacturing defects in welds, forgings castings etc. Radiography provides a quality, cost effective, permanent record with high volume capabilities due to simple operation and portability.

Digital Microfocus Radiography

Digital radiography (DR) is a form of X-ray imaging, where digital X-ray sensors are used instead of traditional photographic film. Advantages include time efficiency through bypassing chemical processing and the ability to digitally transfer and enhance images. Also less radiation can be used to produce an image of similar contrast to conventional radiography.

Instead of X-ray film, digital radiography uses a digital image capturing device. This gives advantages of immediate image preview and availability; elimination of costly film processing steps; a wider dynamic range, which makes it more forgiving for over- and under-exposure; as well as the ability to apply special image processing techniques that enhance overall display of the image.

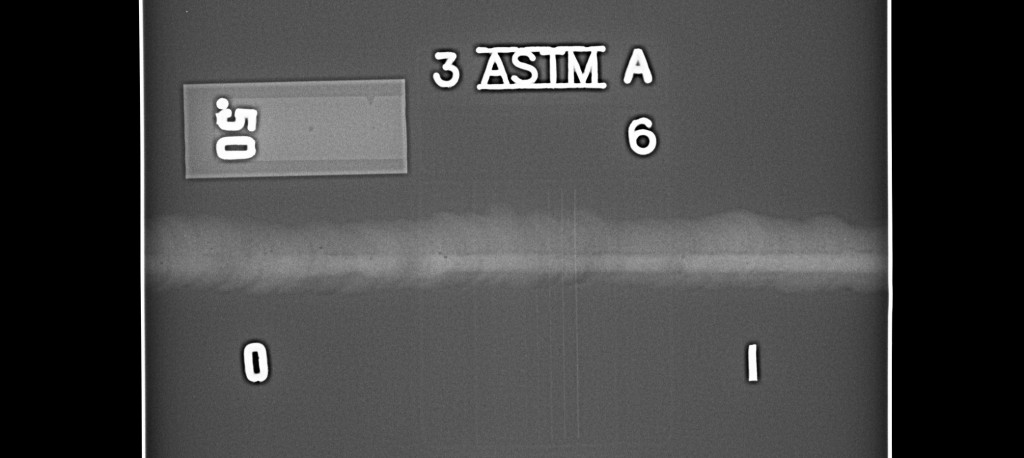

Computed Radiography

Computed radiography (CR) uses a cassette similar to a film cassette. The cassette holds a phosphor imaging plate (IP) which stores the x-ray energy in proportion to the intensity it receives. The plate is inserted into a laser reader unit where the data is extracted and converted into a digital image which is then evaluated on a high resolution display. Digital and computed radiography share similar advantages however, CR imaging plates are less rigid than a digital panel and can be curved to fit the part surface for contact type exposures.

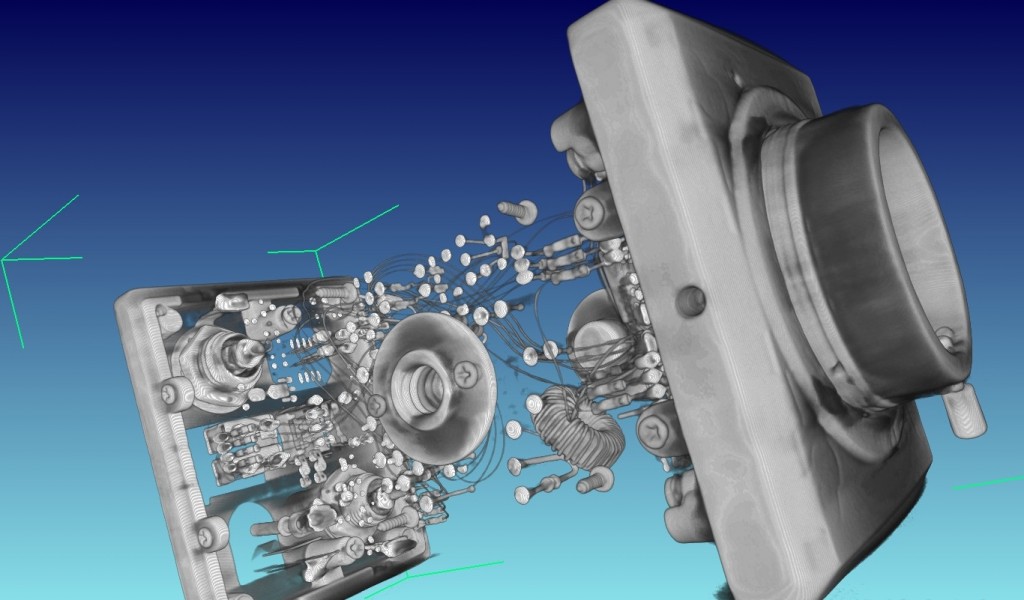

Computed Tomography

Computed tomography (CT) utilizes x-ray equipment to take many images over 360 degrees and combine the data to produce a three dimensional representation of the component. Computed tomography allows our customer to view slices through the part and can be used for failure analysis, flaw detection, reverse engineering and metrology.